Our Capabilities

Our Services

The continued willingness of everyone at Wagner Machine Co. to try new and challenging things has made all the difference for us.

Matt D.

Our company contacted Wagner about having some specialty parts milled for o high profile project at the studio. They went above and beyond to help us understand how to accomplish this to the standards we required, listening carefully to our questions and concerns, and helping to educate us on the different technologies and processes. It is rare to encounter a company that approaches a potential customer with the honesty and integrity that Kurt and Jeff demonstrated. I am looking forward to our next opportunity to work with this company!

Megan R-A.

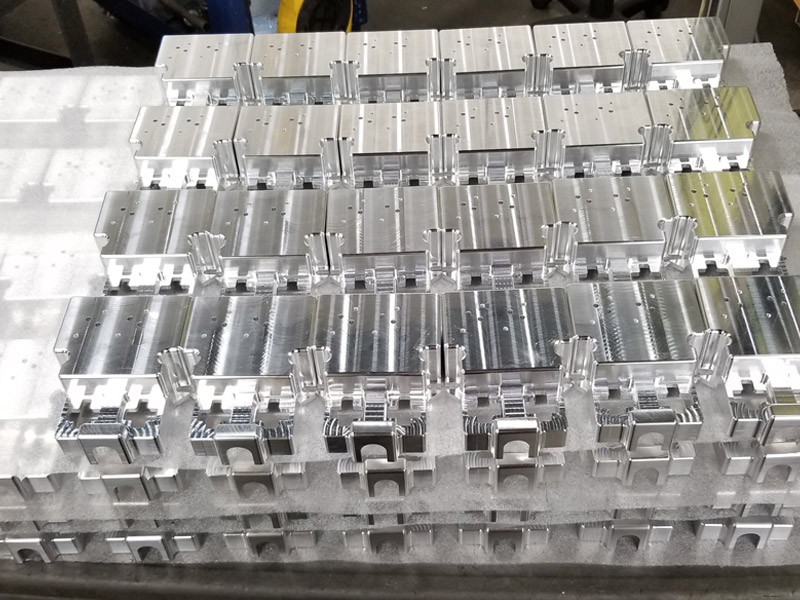

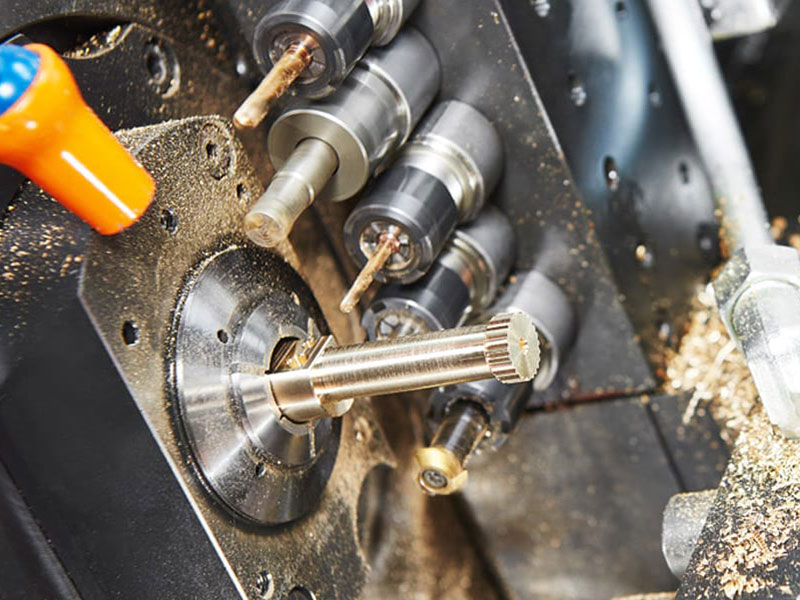

I've been very impressed working with the people at Wagner. Wagner completes projects rapidly and excellently because of their experienced employees and diverse machining capabilities. They have automation capabilities for high volume parts, but also a shop set up just for custom or prototype one-off's. 100% recommend Wagner if you want something done well and done fast.

Lucas D.

Needed to have some parts waterjet cut at short notice, and Wagner were helpful and friendly with a very fast turn-around time.

James A.

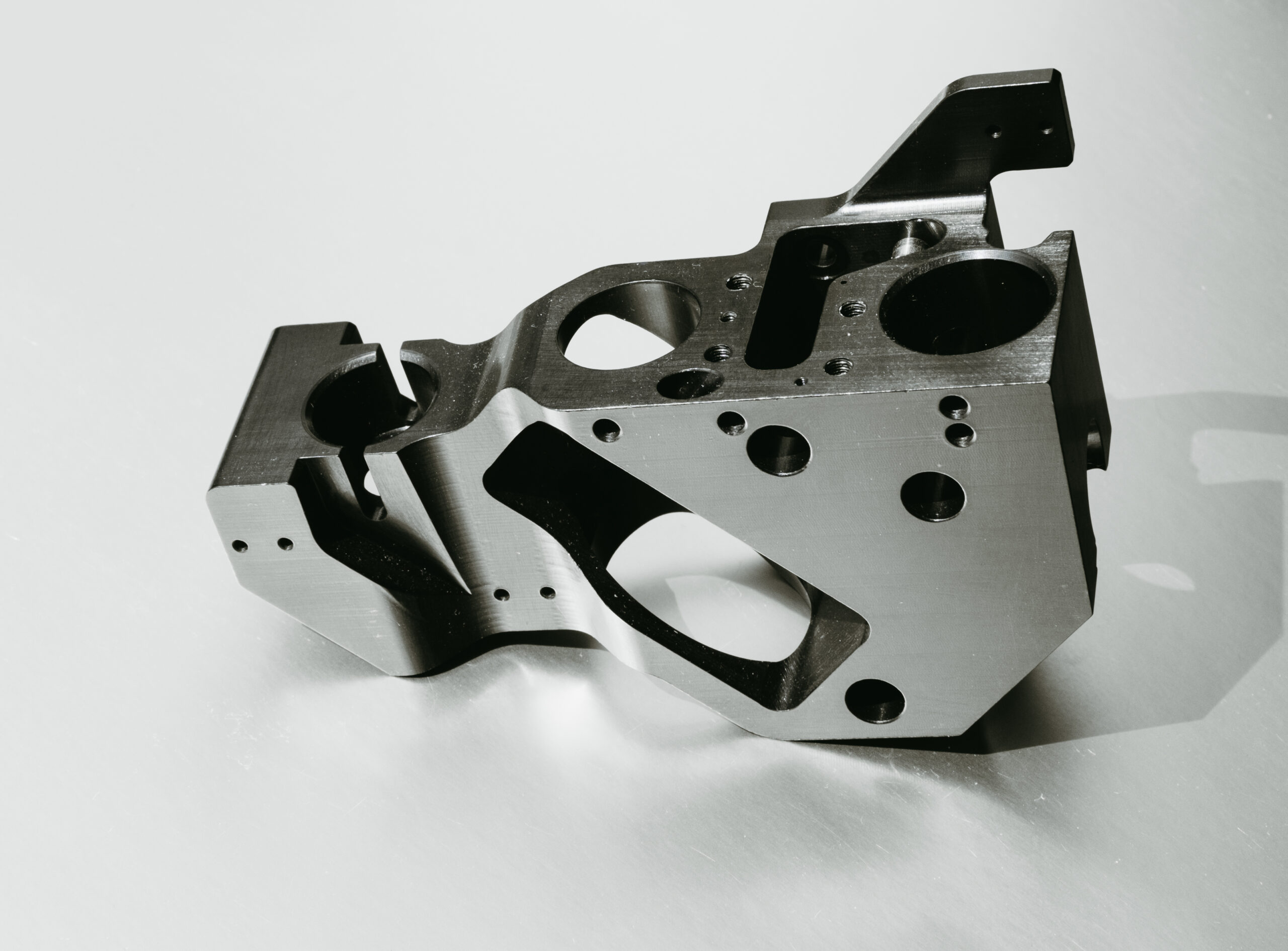

Wagner Machine Co is a top notch machine shop. They have a significant inventory of equipment for parts metal/plastic manufacturing, and low costs for high quantity items. They can make just about anything out of metal, which is very nice for complex prototypes. Be prepared to pay a little more for one off items, but they have good quality workmanship. Don't expect to have to go back and forth on silly mistakes here. They know what they are doing. If you ever need help, just stop in and ask. They are available to walk you through how to machine your part or improve its machinability/cost.

Joe M.