Our Lathe Department

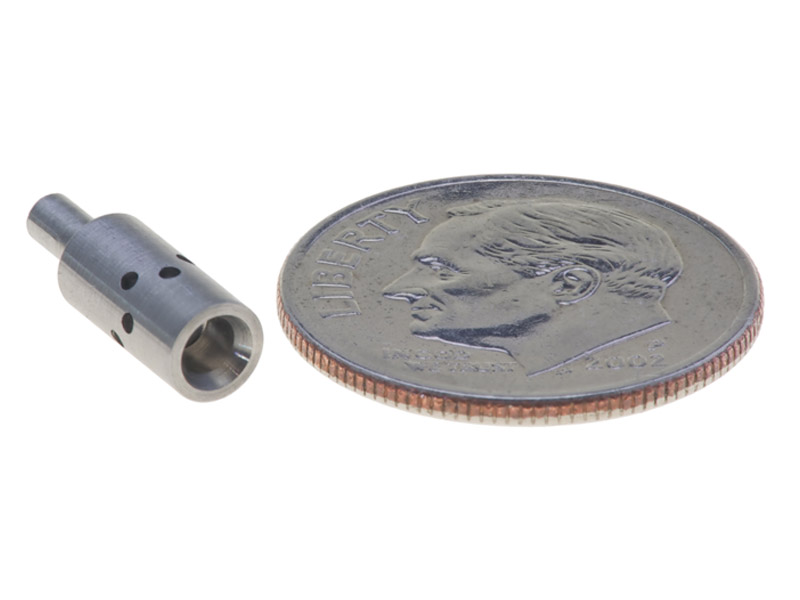

Our production lathe department has the equipment, employees, and software to make your parts quickly and consistently. We specialize in small to medium sized parts of any material or complexity and can hold tolerances of .0001” (.0025mm). Chucker capacity ranges from 6” to 12” with 3″ bar capacity, live tooling, and Y-axis. Collet machines can handle up to 2.625” bar and swiss machines can run bar up to 1.25” diameter. Our collet and swiss machines are multi-channel with sub spindles which allows multiple tools to work simultaneously. They also have bar feeders, live milling tools with Y-axis, and front or rear part ejection for automated machining.

Many of our lathes have overlapping capabilities, and more than half of our lathe department is automated. This gives us the capacity and flexibility to handle your production needs regardless of quantity, complexity, or material. We also offer many related processes, such as centerless grinding, cylindrical grinding, and honing.

Our Experience

We purchased our first CNC lathe in 1986, and now we have more than 20. Our extensive background in prototype machining has earned us a reputation as the go-to shop for complex turned parts. This reputation carries over to our production departments that regularly machine complex, tight-tolerance parts in high volume. Advanced CAM software allows us to quickly and accurately program directly from customer CAD files. To support our production departments and ensure the highest quality, we use multiple Keyence IM systems for automated part inspection.

We document every job, by saving the programs, setup sheets, and digital pictures of each setup. Included in that information are any deburring and finishing notes. We also keep a tooling pack that contains any custom fixtures or special tools that are required for the job. Everything is integrated into our ERP system. This documentation allows us to quickly set up your job in the future, and helps us to guarantee consistent part quality from one run to the next. The addition of ISO9001:2015 and AS9011D certification shows our commitment to high standards of quality and customer service.